CMJ-HSK

Coping Machine

The CMJ-HSK is a machine designed for chip free coping or tenoning of either square or profiled parts without the need for a back-up piece or chip breaker. Two independent spindles with the HSK tool changer is a great fit for medium to large shops that need to quick-change between multiple profiles per day.

CMJ-HSK Advantages:

- No backer board or chip breakers required

- Tear out free parts every time

- Accurate spindle adjustment for tool alignment

- Part stays fixed while the carriage moves

- Dual Air-Locking Spindles

- Side and Top clamps

Material Machining Capacities:

Length: Min: 3″, Max: Not Applicable

Width: Min: 1.5″, Max: 12″

Thickness: Min: 1/2″, Max: 1″

Depth of cut: 5/8″ Max

X Axis – Pneumatic cylinder

X – Axis Guides: High precision Square rail guides & bearings for all linear motions

Electrical – 3 phase, 208 – 230 volt, 60 cycles, 30 amps

Compressed Air – 90 psi at 5 CFM

Dust collection port – 2 each 4″ ports. Total CFM: 696

Width – 52″

Depth – 30″

Height – 57″

Weight 1350 lbs. (approximate)

Specifications may be modified. Contact your Pillar Machine Sales Manager for details.

CMJ-HSK Machine Description

Our coping machine provides a clean, tear-out free, end coped/tenoned part every time!

Pillar’s CMJ-HSK coping machine is designed to create end coping/tenoning for rail ends, as well as finger jointing or end matching – all in one machine.

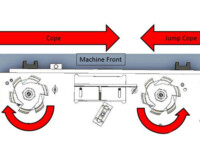

Standard Operation

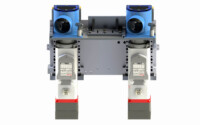

CMJ-HSK machine uses a PLC control for simple and easy to use controls. It is manually operated with 2 counter rotating vertical spindles. One spindle clears the leading edge of the rail with the other spindle then moving in and processing the remainder of the components width. This machine has 2 independent HSK spindle motors with a quick-release tool change feature. If you run multiple profiles a day, the cycle time of 6-8 seconds will save you hours of time.

What the CMJ-HSK Does

The CMJ-HSK is typically used to perform the following operations:

- Shapes the tenoning joint of a moulding, door, or frame part.

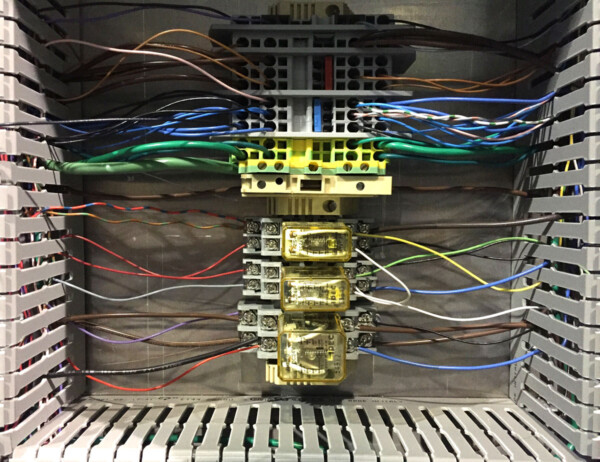

Pillar Electric Cabinet

CMJ-HSK PLC

The machine uses a PLC control for simple and easy to use controls. PLC is an acronym for Programmable Logic Controller: an industrial microprocessor-based controller with programmable memory used to store program instructions and various functions.

What Comes with the CMJ-HSK

Pillar CMJ-HSK One-Piece Welded Frame

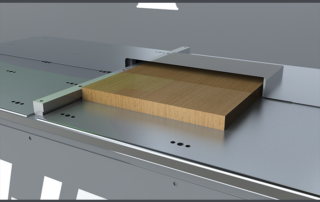

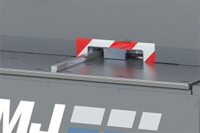

Pillar CMJ Work Surface

Pillar CMJ-HSK Automatic Carriage

Pillar CMJ Counter-Rotating Spindles

Pillar CMJ Tooling

Pillar CMJ Back Fence

Pillar CMJ Side Clamps

Pillar CMJ Top Clamp System

Pillar CMJ-HSK Controls

Pillar CMJ Dust Collection

Installation Requirements

Factory installation is not necessary for this machine. It will arrive fully assembled and ready for production once necessary power and air are connected to it.

Phone support for startup is offered on this machine at no charge.

Factory on-site installations are available if preferred. Contact your Pillar Machine representative if interested in obtaining a quote for this option.

Made In The USA

All Pillar Machine Machines are built 100% at our Salt Lake City Factory.

The benefits of purchasing an American made machine extend far beyond simply supporting the “local” economy.

Additional benefits include:

- All parts are sourced from vendors in North America.

- Parts availability is increased and assures honest pricing.

- Real Factory Support.

When technical assistance is required you can often talk directly to the people that built, wired, and tested your machine.

1 Year Warranty

Pillar Machine warrants to the original purchaser of the Pillar Machine Machinery that this product will be free from defects in material or workmanship, when purchased, and under proper, normal use, for one (1) year from the original date of delivery. Original purchaser understands that the machine warranty is only applicable to machines that are or were paid in full within 60 days of the original delivery date.

The full defined warranty can be found here: https://pillarmachine.com/pillar-service/#warranty

Options for the CMJ-HSK

Pillar CMJ Additional Guarding Option

An additional rear guarding option adds to the machine with hinged access doors. The doors are made of tube steel and expanded metal.

Notes:

1. This option is a welded feature installed during manufacturing.

2. Selecting this option may increase your machines lead time.

3. This option does not include an electronic interlock.

4. When this option is used, it increases the depth of the machine to 40″.

Pillar Keyed Electronic Interlock

Keyed Electronic Interlock option gives instant switch access to the rear guarding hinged access doors and acts as an “Emergency Stop”.

Notes:

1. Photo may not represent the exact switch to be used on the machine.

2. Selecting this option may increase your machines lead time.

Pillar CMJ Foot Pedal Control

A foot pedal control option will convert the machine from a palm button start switch to a foot pedal start switch.

Notes:

1. Selecting this option may increase your machines lead time.

2. Photo may not represent the exact foot pedal to be used in this option.

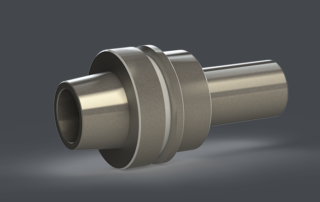

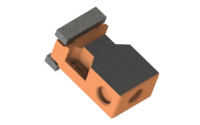

Pillar HSK Tool Holder

Optional tool holder includes one pair of tool holders for the CMJ HSK machine.

Notes:

1. Arbor specs: 1 1/4 X 55 mm HSK-63F.

2. Photo may not represent the exact oiling device to be used in this option.

Pillar Machine Automatic Oiler

Optional automatic oiler adds a compressed air automatic oiler to the frequently used bearings on the machine. The oiler uses oiled compressed air to deliver lubrication to the linear bearings. Because of the nature of this option, the bearings operate under positive pressure making them less susceptible to dust contamination.

Notes:

The oil injection amount can be adjusted using an adjustment knob on a pneumatic oiler at the machine.

The oiler will operate anytime the spindle is spinning.

The bearings that are oiled are:

a. 4 each X-axis linear bearings

b. 4 each under Drill spindle linear bearings

c. 4 each under Groove spindle linear bearings

Photo may not represent the exact oiling device to be used in this option.

Selecting this option may increase your machines lead time.

Pillar CMJ-HSK Optional Tooling

For additional cost, we will setup one profile of your tooling in Salt Lake City before the machine ships to you. If you would like Pillar Machine to setup more sets of tools, you will need to select this option and tell us how many setups you would like.

Notes:

1.If Pillar is setting up you’re tooling you will need to provide Pillar with the HSK arbors and shims needed to perform this setup for each tool (including the first profile that is included) that is needing to be setup

2. Selecting this option may increase the lead time of your machine.